Search

On May 1, Labor Day, the construction of the roof cable structure of the Dalian Barracuda Bay Football Stadium project was completed on schedule, and it was a solid step forward from the perfect completion.

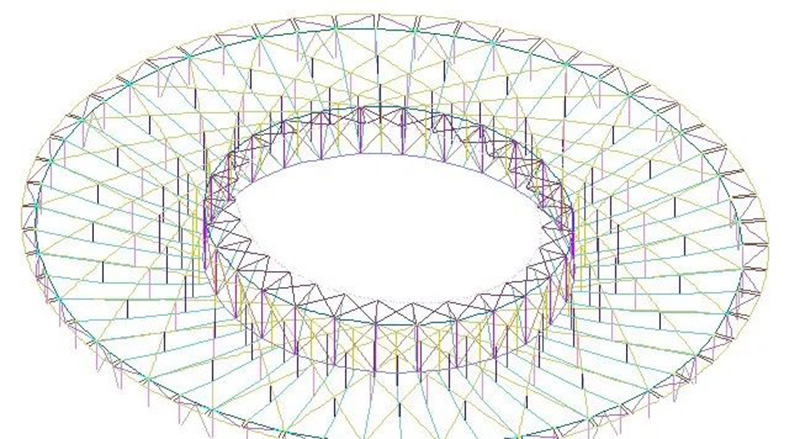

The cable structure is the skeleton of the roof of the football field. It supports the roof membrane structure like an umbrella rib, including the lifting of the upper ring cable, the installation of the strut, the lifting of the cable, and the construction of the cross cable. The construction is extremely difficult and the precision requirement is extremely high. It is the key line node of the project, which directly affects the construction of the subsequent sub-projects such as roof membrane structure and sports technology.

The canopy cable structure of the project is designed as a spoke-type upper oblique lower radial flexible double-layer cable net system, which is the first design and adoption in China. The overall lifting weight reaches 2,600 tons, the maximum cable diameter reaches 125 mm, and the overall cable internal force value exceeds 40,000 tons. The lifting weight and construction difficulty are the highest in the world.

In the end, the cable materials used in the project are all domestic high-vanadium airtight cables and optical fiber smart cables, which are the first batch applications in similar projects in China. The lifting process is also the first domestic construction design concept of ground assembly, overall high-altitude synchronous lifting and tensioning.

In order to ensure the "one-step improvement", the project team used the whole-process construction simulation simulation system to conduct simulation calculations, gradually explored the size of the prestress that needs to be applied to each cable, and selected suitable construction equipment such as tension jacks. During the upgrading process, at each stage of upgrading, the project team must conduct a morphological analysis of the cable to further optimize the plan, improve the construction quality and speed up the construction progress.

The roof structure of the football field adopts a spoke-type upper oblique lower radial flexible double-layer cable net system. The structure adopts a double-layer cable net arrangement. The span of the cable structure is 253m, and the thickness of the cable structure is 19.5m. The lower layer is radially arranged cable nets with a diameter of φ120mm, the upper ring has 4 cables with a diameter of φ100mm, and the lower ring has 8 cables with a diameter of φ125mm. Ring beam structure, the maximum length of the upper inclined cable reaches 80m, and the cable body is Galfan sealing cable.

The upper diagonal cable clamp is divided into 5 circles according to the structure, namely U2, U3, U4, U5, U6. The design of the cable clip node is complex, with many angles, and the manufacturing process is difficult. In order to ensure the quality of each casting, the technical team makes the product safer and more reliable through casting simulation analysis.

84 sets of U2, U3, U4 upper diagonal cable clips 56 sets of U5, U6 upper diagonal cable clips

The cable force monitoring scheme of this project adopts connecting screw stress monitoring and fiber grating smart cable, which is the first batch application in similar projects in China.

The connecting screw is used to adjust the length of the cable. When the cable is loaded, the connecting screw directly bears the tensile force, and its surface strain has a linear relationship with the cable force. Each cable is equipped with 4 strain sensors at the connecting screw, which are evenly distributed on the measured section at a 90-degree angle. The force magnitude and principal stress direction of the connecting screw can be obtained through calculation, so as to achieve the purpose of monitoring the cable force.

A groove is prefabricated on the Z-shaped wire on the surface of the sealing cable body, and a fiber Bragg grating is embedded in the groove to make a fiber Bragg grating cable force sensor for an intelligent cable. Considering that the strain measurement requires a certain symmetry, a double slotted cable is actually used, that is, two symmetrical Z-shaped wires are selected on one cable to reserve slots.

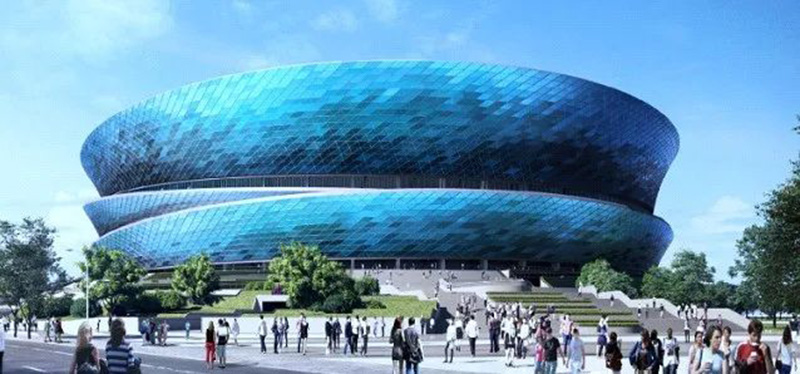

Dalian Barracuda Bay Professional Football Stadium is a complex architectural system composed of various structural forms such as steel structure, cable structure, membrane structure and metal curtain wall structure. The canopy system of the project is PTFE tensile membrane + ETFE air pillow membrane, covering an area of about 40,000 square meters and formed by 252 membrane units.

The outer curtain wall adopts a single-layer ETFE film supported by parallel cross cable nets, covering an area of about 37,000 square meters, and is composed of more than 20 kinds of blue. The difficulty of design and construction is at the forefront of domestic membrane structures. Among them, Jianyijia φ55, φ40, φ30 Galfan cables, φ40 steel tie rods, and more than 30,000 sets of point-supported carbon steel barge joints are used.

The total construction land area of the project is 185,000 square meters, the total construction area is 136,000 square meters, and the seats are 63,000. The roof shed is a cable truss structure, and the plane projection outline is a four-centre circle. The span of the structure is 253 meters, the largest span among similar structures in China.

The roof is a double-layer cable net structure, the upper layer cables are arranged diagonally, each diagonal cable crosses with other 5 other diagonal cables, and the intersections are connected by cable clips. The novel and unique structural form controls the positional shape and the installation of the cable clips. Timing is extremely demanding. In addition, the specification of the cable in this project is large, the internal force of the cable is large, and the total lifting load is the largest among the same type of stadiums in China.

In addition, the geographical location of Dalian makes the key upgrading stage of the project facing the challenges of winter construction and strong wind construction. In view of the weight and difficulty of the project, it was finally decided to introduce additional cables and tensioning methods to solve the problem of excessive force during the lifting process, and to ensure the safety of construction to the greatest extent.

The project started construction in October 2020. It is planned to be completed, accepted and put into trial operation in December 2022. It is planned to hold a test competition in April 2023, and officially host the Asian Cup from June to July 2023.

This article is reproduced from the public account:

China Construction Eighth Bureau Northeast Company, Jianlong Hardware, Beijing Institute of Architectural Engineering

Copyright © Zhejiang Wanhao Group Co., Ltd. All Rights Reserved.

Sitemap | Technical Support