Search

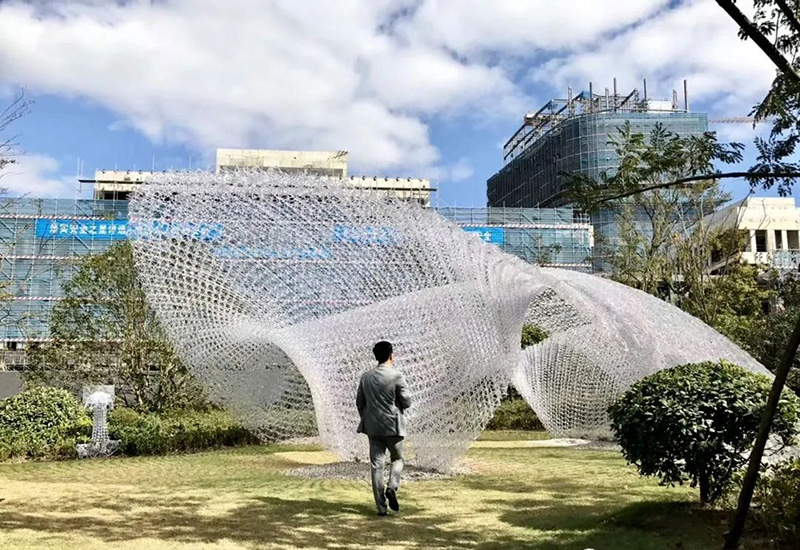

In 2017, Tongji University, in collaboration with "Chuangmeng International & Yizao Technology", used MP (Modified Plastic) materials for the first time to realize the overall 3D printed structural performance pavilion - "Cloud Pavilion" in Shanghai Lingang New City, China, and successfully completed. "Cloud Pavilion" is constructed by large-scale spatial printing, abstracting the form into a spatial grid, and then constructing by grid printing. It has unique advantages in the integration of large-scale printing efficiency and structural performance, and is a very promising architectural 3D printing technology solution.

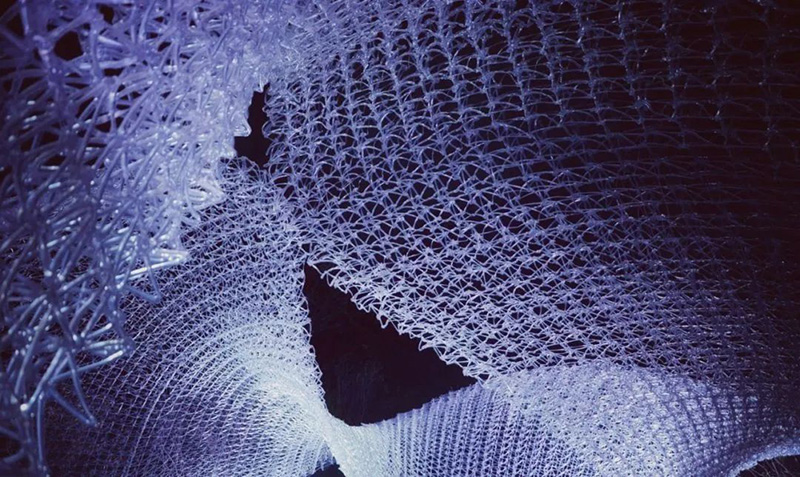

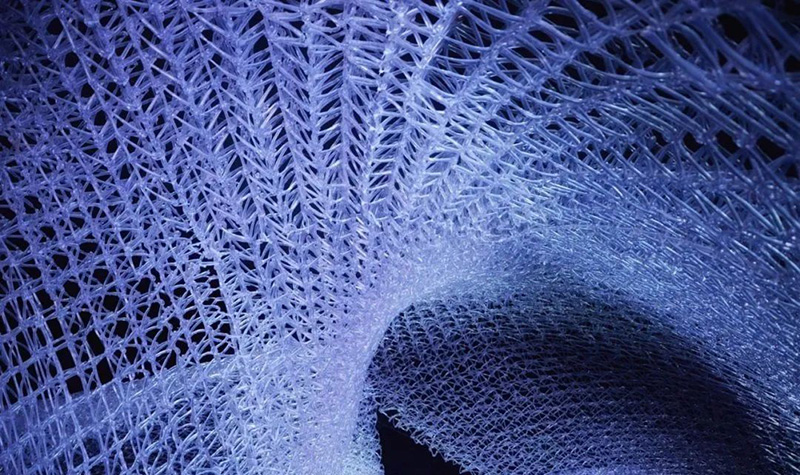

The "Cloud Pavilion" project aims to combine structural performance-based design techniques with robotic construction, which is completed and demonstrated in a highly integrated manner. In the design of "Cloud Pavilion", topological optimization algorithm based on structural performance analysis is used to generate architectural form through structural performance technology, and then the stress distribution is transformed into a grid system, so as to obtain a variable density grid form. At the same time, in the process of design, how to realize the robot space printing of network unit is fully considered.

The whole network prototype unit system consists of five different cell paths with different densities. The dense unit is mainly used to bear the self-weight load, while the sparse unit mainly plays a covering role, which makes the seemingly complex network system feasible with the support of robot space printing technology. Based on the support of digital design and robot construction technology, "Cloud Pavilion" shows the full integration of structural performance analysis technology and architectural form aesthetics.

The construction of large-scale exhibits produced by the robot space printing process mainly focuses on the realization of reasonable "materialization" construction of abstract architectural modeling, that is, the most effective space grid is generated by a specific programming language to achieve continuous construction, and strive to achieve the lightest overall structure and the least amount of materials, which greatly improves the construction efficiency and saves considerable material expenses. In July 2017, Tongji University completed the 14-meter span MP 3D printing pedestrian bridge, using the technical solution of layered 3D printing. The laminated 3D printing scheme has advantages in overall strength, but the material consumption is relatively large, and the disadvantages of large self-weight also exist. Therefore, the printing of "Yunting" by Tongji University is to achieve the goal of more structural and efficient material saving in further research.

The geometric prototype of the pavilion was selected as a complex surface with a length of 11 meters, a width of 11 meters and a height of about 6.0 meters. Due to the excessive curvature of some areas of the surface and the excessive length of the front overhang, the traditional homogenized space printing method is difficult to print this form. In addition, such a large-scale component will face many structural problems in the design stage. The design team is not satisfied with the status quo of space printing, and hopes to find a new robotic space printing process to achieve an integrated design of perfect integration of architectural form and structural performance. In the design, the structure topology of the pavilion is optimized, so that the structural performance of the building is fully considered in the initial stage of design.

Taking into account the size of the robot working space and the appropriate manual operation range, the pavilion is divided into 35 pieces, each with a length range of 5-7m and a height range of 1.5-2.5m, and is printed by KUKA robots. When the curvature of an individual surface is too large, the block will also be subdivided into smaller sizes to meet the job requirements of robot space printing.

Because the space printing has strict control over the discharge speed of the extrusion head, the space printing speed is much lower than the laminated printing. In this case, the processing time was 500 hours, and the two robot kits took a total of 21 days. The robot prints from left to right according to the imported programming language. After completing the printing task in the horizontal direction of the first row, it moves vertically upward to the starting coordinate of the next row, then completes the printing task in the horizontal direction of the second row from right to left, and completes the printing task of all the blocks according to this logic.

All components are prefabricated in the factory, numbered, segmented and polished, and then shipped to the site in batches ready for installation. The entire installation process takes less than one day, thus achieving a fast, green and pollution-free installation environment. The main setup process consists of the following steps:

1. Locate the 4 support coordinates of the pavilion, and carry out pre-burial processing;

2. Rely on the scaffold and steel plate prepared in the site to fix the 4 components on the ground;

3. Take the 4 fixed components as the starting point, start the assembly in turn, and use the cable tie to fix the adjacent two components;

4. After completing the assembly of all components, remove the on-site scaffolding

In the future, this robot space printing technology will have broad application prospects in complex space structures, special-shaped templates, and rapid shape finding. In the next step, the research and development team will further explore the deepening and improvement of materials and processes as well as the research and development of supporting processes, and push the large-scale space printing technology for construction to a more reliable and extensive industrial application.

Project profile

Project name: Cloud Pavilion

Digital Design and Construction team: Tongji University, Alliance International + Yizao Technology

Address: Port City Square, Lingang New Town, Pudong New Area, Shanghai

Device size: 11Mx11Mx6M

Design time: July 2017 - August 2017

Construction time: September 2017 - October 2017

Design team

Host designer: Yuan Feng

Concept design: Yuan Feng, Han Li, Gao Weizhe

Structural performance

Design: Chen Zhewen, Chai Hua, Wang Jin, Shen Wei

Digital construction: Zhang Liming, He Sizhong, Dai Shilong, Chen Zhewen

Photography is by Chen Hao Lin Bian Lin Yuqiong

Source: School of Architecture and Urban Planning, Tongji University

This article is reproduced from the public number: Tongji University

Copyright © Zhejiang Wanhao Group Co., Ltd. All Rights Reserved.

Sitemap | Technical Support