Search

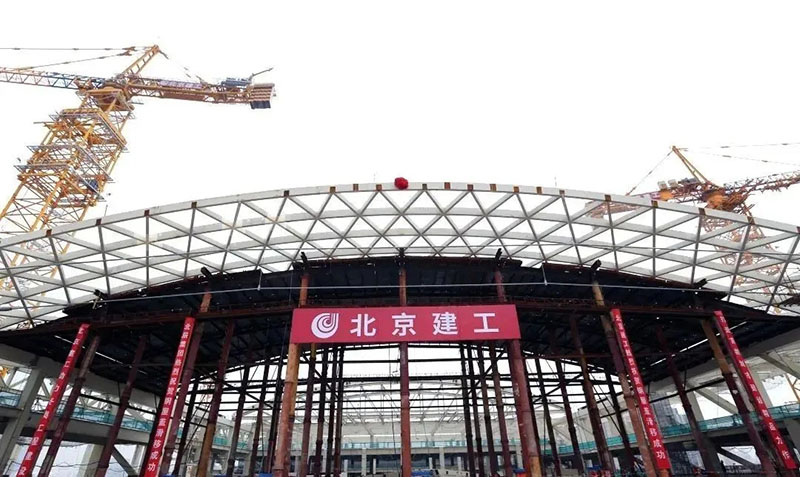

At 9 a.m. on June 29, the steel structure roof reticulated shells in the exhibition area of the second phase of the National Convention Center, which was constructed by Beijing Jishi, began sliding installation, which also marked a step closer to the overall capping of the main structure of the project.

The total construction scale of the second phase of the National Convention Center in the Beijing Olympic Central Area is about 770,000 square meters, with a total length of 460 meters and a width of 150 meters. The total steel consumption is 126,000 tons. The main building consists of the conference area, exhibition area and between A welcome hall is formed between the participants. During the 2022 Beijing Winter Olympics, it will be put into use as the main news center and international broadcasting center.

The amount of steel used for the steel roof lattice shell under sliding construction is about 2800 tons, the length is 168 meters from north to south, the span from east to west is 72 meters, the steel roof lattice shell area is large, the height from the ground is 44 meters to 52 meters, the high-altitude operation is large, and the components The hoisting times are up to 3000 times, the hoisting time is about 2 months, the construction period is tight, the welding accuracy and quality requirements of the steel structure are extremely high, and the roof lattice is a cable bearing structure, which is difficult to control the deformation.

The steel structure reticulated shell installed this time is located on the top floor of the second exhibition area of the Congress. It is arched, like a steel bridge spanning the steel beams on the east and west sides. The highest point of the arched roof reticulated shell is 20 meters away from the top floor. A total of 56 small steel bridges are being constructed on the roof lattices under construction. Each small steel bridge has an east-west span of 72 meters and a width of 3 meters in the north-south direction. First, small pieces are assembled on the ground, then they are hoisted to the air platform for assembly, and finally divided into steps Push and slide, carry out welding and fixing according to the order of the plan after the sliding is in place, it is expected that the steel roof will be unveiled as a whole in early August.

Steel roof reticulated shell sliding "three steps"

The first step: ground small fight

After assembling multiple small steel components into small steel bridges on the ground, they are hung on a 20-meter-high aerial operating platform.

Step 2: Assemble the high-altitude platform

Set up two high-altitude operation platforms on the top floor of the exhibition area, respectively spanning 3 equal parts on the roof, first put 6 small steel bridges into a sliding unit on the high-altitude platform, and then put on each small steel bridge "Slipper" for slippage construction.

Step 3: Push and slide into place

Before sliding, slide rails are set in advance, and two hydraulic jacks and synchronous sensors are installed at both ends of the steel bridge, and the sliding is pushed from the two platforms to the two sides, and the steel cable is stretched every 6 meters. , To ensure that the roof structure is stable, and finally slide the roof to the design position.

Slip construction technology refers to a construction method in which a grid unit slides to a design position on a slide rail set in advance. According to the records of the enterprise history, in 1977, Ji Shi Company adopted the high-altitude sliding installation method to complete the sliding construction of the steel roof truss of the Chinese aided construction of the Zaire People’s Palace Conference Hall Project; in 1979, Ji Shi Company adopted the high-altitude sliding installation process The fabric roof construction of the Syrian Damascus Stadium was completed. According to the earliest summary document of the slip method construction in my country, the machine construction company is the earliest enterprise to use slip technology for construction in my country, and the initial term used was "sliding installation construction technology".

Over the years, Beijing Jishi has summarized and applied for a number of patents based on the sliding technology. The invention patents include "High-span in-situ construction technology of super-long-span open-string arch steel structure" and "Sliding of large-span open-string steel arch truss" "Construction Technology", utility model patents include "a steel structure sliding mechanism" and "BJZ-40 computer-controlled automatic hydraulic pushing device", etc. These technical achievements have made Beijing Jishi maintain the steel structure sliding construction technology. Industry leading position.

This article is reproduced from: Beijing Construction Engineering Machinery

Copyright © Zhejiang Wanhao Group Co., Ltd. All Rights Reserved.

Sitemap | Technical Support