Search

Inflatable membrane structure has been applied more and more in our life in recent years. Because of its unique performance and affordable price, it is very popular. What are the methods of cutting the inflatable membrane structure? What are the specific characteristics of each method? Let's take a look at the Wanhao membrane structure.

The cut of the inflatable membrane structure is a curved surface model according to a certain proportion, and is cut into a corresponding shape by a certain width of paper, cloth or other flexible material, and is pasted to the model repeatedly, and is then determined to be intact, and then determined by a computer method. At present, the commonly used cutting methods include the geodesic cutting method and the plane intersecting cutting method, which are respectively introduced as follows.

1. Geodesic cutting method

Geodesic is a concept in geodesy, also known as geodesics, which is generally understood to be the shortest curve that passes through two points on a surface and exists on the surface. The geodesic on the developable surface is a straight line after the surface is expanded into a plane; the geodesic on the non-expandable surface is close to a straight line after being expanded. Geodesic cutting method is to divide the space film surface by geodesic. Finding the geodesic problem on a surface is actually a matter of finding the functional the length of the curve between two points on the surface.

The problem of using the geodesic concept as a tailoring analysis of the membrane structure is complicated by the novelty and change of the geometric shape of the membrane structure. Through the shape-finding analysis, the spatial coordinates of some discrete points on the membrane surface are obtained, instead of the equations of the space surface, and thus the explicit expression of the function of the curve length between two points on the surface cannot be obtained. The piecewise linearization method is usually used to deal with this problem, that is used to determine several points on the geodesic, and then the linear interpolation method is used to obtain the intermediate point, thereby obtaining the geodesic.

For some curved or curved areas with spherical features, there are countless geodesic lines between the two ends (poles), that is, the geodesic is not unique, which makes it difficult to control the maximum width of the strip. A quasi-measurement method that specifies an intermediate point between the two ends is proposed for use in the membrane structure design software EASY.

The advantage of the geodesic cutting method is that the seam is the shortest and the materials used are less, but the distribution of the cutting line and the consideration of the warp and weft directions are difficult to grasp. In practical applications, when a spatial membrane strip surrounded by two geodesic lines and boundaries is developed into a plane, one of the geodesic lines needs to be designated as a straight line.

2. Planar intersecting cutting method

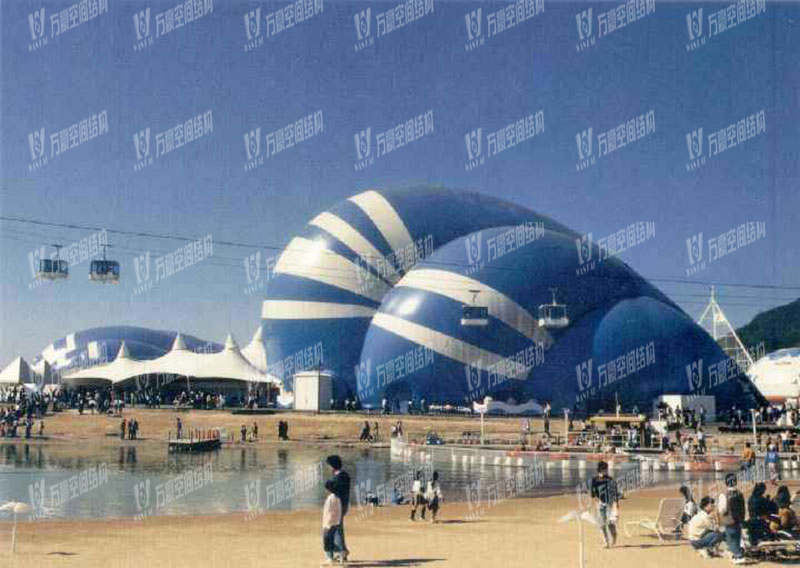

Planar intersecting cutting method is to use a set of planes (usually with vertical planes) to cut the shape of the surface, and divide the membrane surface into individual "banana-like" strips, which are cut by the intersection of plane and space surface. The plane intersecting cutting method is often used for the cutting of the symmetrical membrane surface, and the obtained cutting line is relatively neat and beautiful.

3. Connectivity of the membrane

Connection Method of the membrane connection is mechanical connection, sewing connection, thermal connection and so on. The metal membrane is bound to the edge of the two diaphragms and the diaphragm is connected together with the mechanical splint at the overlapping position, and the mechanical connection is commonly used in the large-scale structure of the membrane and the membrane surface of the field splicing. The sewing connection is sewn by sewing machine. When using sewing connection, it is important to select the strength and durability of the sewing line. The sewing connection is usually used in the weak-like membrane structure of the waterless structure, or the coating is applied to the corner of the PVC coated polyester fabric at the same time as the thermal connection. The thermal connection is also known as the welding of the membrane, which is a contact with the heating object, or by high-frequency electromagnetic wave, or a heat-emitting air to the membrane, so that the membrane is obtained by the heat of the coating on the fabric and then applied pressure and cooling the membrane. The thermal connection is the most commonly used film connection method. The PVC material, multi-use high-frequency welding, local repair can be used for hot air welding; PTFE and ETFE membrane is used to heat the heating object of the high temperature thermal method. The seam can be lap, also can be use of stripes stitching, PTFE film welding need for two-layer PTFE plaster-based precipitate (FEP) membrane strip.

Copyright © Zhejiang Wanhao Group Co., Ltd. All Rights Reserved.

Sitemap | Technical Support