Search

As a kind of load-bearing structure system, steel structure has many advantages, such as light weight, high strength, good plasticity and toughness, superior seismic performance, high degree of industrial assembly, short construction period, significant comprehensive economic benefits, flexible structure system, beautiful shape, etc., so it is more and more widely used in industrial plants, urban rail (subway) depot warehouses, large shopping malls and supermarkets And other large-span or super span buildings. Corresponding to its construction technology, it is necessary to build large reinforced concrete foundation or equipment foundation for these buildings, and bury structural bolts connecting steel structure (column) and reinforced concrete foundation. Because the steel structure foundation is large (the upper part is mostly in the shape of a quadrangle), the bolt hanging in the air is not easy to fix, and the steel structure installation quality requirements are high, so the embedding accuracy of the coupling bolt becomes the key technology of the steel structure installation construction.

01 process principle

The independent support system and set mold are used to locate the embedded bolts. After precise adjustment and calibration by theodolite or total station, the concrete cushion cap pouring is completed once, so as to achieve the accuracy of the embedded position. The characteristics of the process are as follows:

(1) due to the use of set mold steel plate to fix the embedded bolts, the relative position of the bolts in the bolt group is kept accurate.

(2) using independent support system and set mold to embed bolts, the bolts have fine adjustment, high construction accuracy and small overall deviation.

(3) make full use of Φ 48 mm steel pipe scaffold and fastener turnover materials commonly used for erecting scaffold, which has strong universality and low cost, and can save a lot of project investment.

(4) the construction process is simple and fast, and the operator can easily master it.

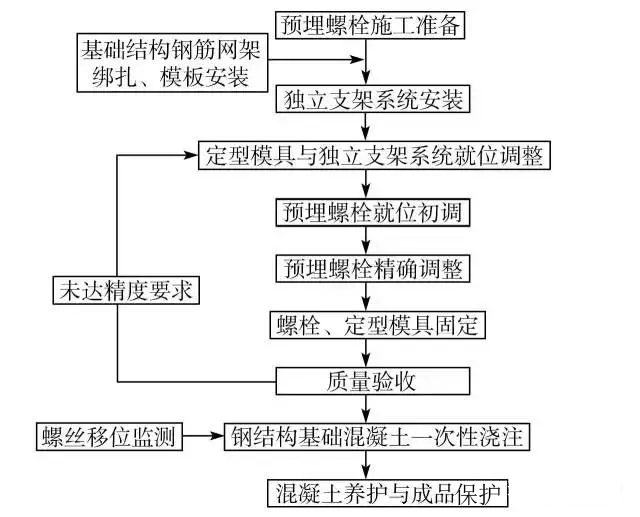

The process flow chart of embedded bolt of steel structure is shown in Figure 1.

02 key points of construction operation

2.1 construction preparation

2.1.1 the processing of anchor bolt shall be customized and accepted according to the design requirements, and the corresponding material certificate and inspection report shall be provided.

2.1.2 design and processing of set mold

(1) according to the relative position of the embedded anchor bolt and the concrete foundation axis, and considering the mold assembly requirements, determine the plane size of the mold steel plate, carve out the cross line of the vertical and horizontal axis of the mold steel plate, then determine the relative position of the embedded bolt according to the mold axis, and drill. The drilling position and hole diameter of the mould shall be completely consistent with the bolt hole position and hole diameter of the steel structure column, and the thickness of the steel plate shall be ≮ 4 mm.

(2) after the die steel plate is processed, it can be assembled on site. The car pole is a short scaffold with a length of 2.0 m, and the vertical bar is made of Φ 18 mm threaded steel or Φ 20 mm steel pipe. The height of the vertical bar should be 5-10 cm higher than the embedded bolt to facilitate the use of steel ruler to check the axis.

(3) if the top of the concrete foundation is short column, it can be considered to dig holes in the center of the steel plate to facilitate the concrete pouring.

2.1.3 control of measurement accuracy

According to the engineering design positioning coordinate and elevation, the axis and elevation control network are densified to facilitate the accurate measurement of different parts.

2.2 construction sequence

According to the plane layout of the steel structure column, the embedded bolts shall be fixed along the longitudinal axis starting from the corner column or side column. If it is a multi span steel structure, it should be constructed by flowing water from the longitudinal axis of the middle span to the longitudinal axis of both sides to reduce the measurement and construction errors and improve the overall installation accuracy.

2.3 installation of independent support system

The design dimension of the steel structure concrete foundation is large, the maximum width is 3.8m, the upper part is usually designed as a quadrangular shape, the formwork height is far lower than the embedded height of the anchor bolt, and the steel formwork or wood formwork has certain flexibility, which can not meet the precision requirements of the embedded bolt. Therefore, a set of independent support system is adopted in the project. The installation points of the bracket are as follows:

(1) pull wires along the longitudinal axis at about 0.75m on both sides of the foundation axis (it shall be ensured to be outside the ground beam), and set up poles between the two sides of the cushion layer of the foundation cushion cap and the foundation cushion cap along the pull wires, with the spacing of 2.0-2.5m.

(2) the vertical pole shall be driven into the foundation soil for 30-50 cm (depending on the hardness of the soil), and the height shall be about 20 mm higher than the longitudinal horizontal pole. The longitudinal horizontal bar must be set horizontally, and the height shall ensure that the embedded bolt top meets the design height, and there is space for up and down adjustment and movement.

(3) generally, the construction width of the foundation bearing platform is more than 2.0m, and the vertical bars on both sides of the foundation and the upper horizontal bar can be connected with diagonal tie rods to form a portal frame; the node spacing between the diagonal tie rods and the horizontal bar is about 1.5m, so as to ensure that the horizontal bar does not produce deflection deformation.

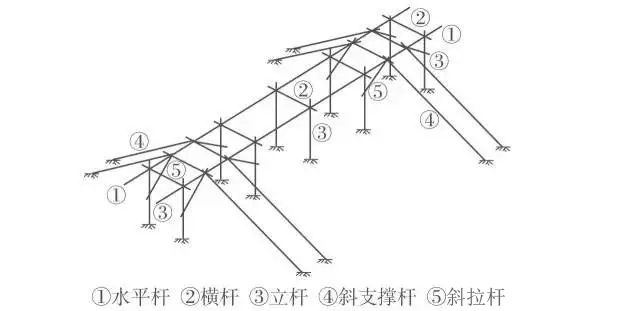

(4) at the joint of the diagonal rod and the horizontal rod, the diagonal support is erected to both sides (the depth of the support driven into the foundation soil is about 30 cm), then the transverse rod is installed near the support, and the well shaped frame is composed of the horizontal rod and the transverse rod at the upper part of the foundation, forming a space geometry invariant body, ensuring the rigidity and stability of the frame (see Figure 2)

2.4 positioning and adjustment of set mold

(1) use theodolite or total station to measure and set vertical and horizontal axis points on the well frame of the support system, draw wires to form a cross axis, then set the shaped mold car pole on the well frame horizontal pole, align the cross mark on the mold steel plate with the well frame axis draw wire, and connect the car pole and the horizontal pole with foot fastener (do not fasten temporarily for adjustment).

(2) after the setting mold is in place, loosen the fastener on the car pole, use a small plumb bob to pull the line from the axis of the well frame to cast a point on the mold steel plate, tap the car pole gently, make the setting mold move slightly from left to right, use the axis pull line on the well frame to adjust it accurately, make the casting point coincide with the mold score, and then tighten the fastener.

2.5 installation and adjustment of embedded bolts

(1) drill the embedded bolt from the die steel plate, reserve the length of the exposed thread according to the design requirements, and fix it with two nuts; use the level gauge to detect the elevation of the bolt top, fine tune it to meet the elevation requirements through the upper and lower nuts, and tighten the nuts (do not screw them up temporarily).

(2) use a horizontal ruler to check the perpendicularity of the embedded bolt and screw in two directions one by one, slightly pull the screw to adjust until the perpendicularity of the two directions meets the requirements, and tighten the nut thoroughly.

(3) when the elevation and perpendicularity of each bolt of a bolt group are adjusted to be qualified, the root of the bolt shall be spot welded and connected with each other with short steel bars to form a whole bolt group. If the embedded bolt is long, one or two welding bars can be added to ensure the accuracy and stability of positioning.

(4) in order to ensure that the embedded bolt does not have overall settlement and overall inclination, it is also necessary to use short steel bars to conduct cable-stayed spot welding with the foundation steel grid, and two short steel bars are diagonally welded at the bottom of the embedded bolt to support the foundation cushion.

(5) when the internal space of the foundation reinforcement grid is large enough to not affect the overall installation of the embedded bolts, the embedded bolts can be installed before the installation of the mold.

2.6 review of embedded bolts

(1) after the embedded bolts of each foundation bearing platform are installed, use total station to measure and set the intersection point of axis on the die steel plate, check whether the intersection point of the steel plate scoring coincides with the intersection point of the measured axis, if there is any error, slightly tap the car bar by loosening the fastener to fine tune the die until it is fully reconnected. If the deviation is too large, the car bar fastener and the reinforcement connection with the foundation reinforcement grid shall be loosened and readjusted.

(2) use a steel ruler to check whether the distance between the bolt groups of each foundation bearing platform meets the design requirements, pull through the line to check whether the same row of embedded bolts of each foundation bolt group are arranged in a straight line, if there is any error, repeat the above methods to correct.

(3) for the steel structure with long longitudinal axis, due to the limitation of vision and instrument, the method of subsection embedding and densification of control network can be adopted, and the recheck measurement with embedded bolts can be strengthened to ensure that the control accuracy meets the requirements.

Copyright © Zhejiang Wanhao Group Co., Ltd. All Rights Reserved.

Sitemap | Technical Support