Search

Project Name: Hengqin International Science and Technology Innovation Center Roof Steel Reticulated Shell and ETFE Air Pillow Project

Construction site: Zhuhai City, Guangdong Province

Completion time: December 2017

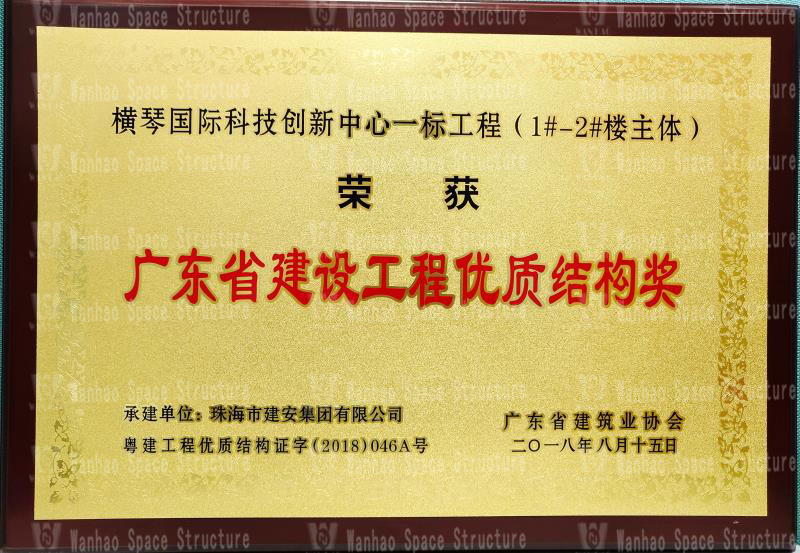

Award grade: Guangdong Province Construction Project Quality Structure Award

Winner: Ningbo Wanhao Space Structure Engineering Co., Ltd.

I. Project Overview

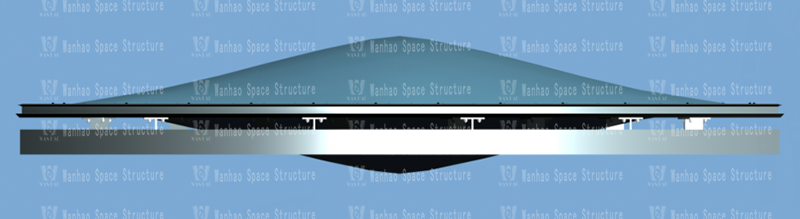

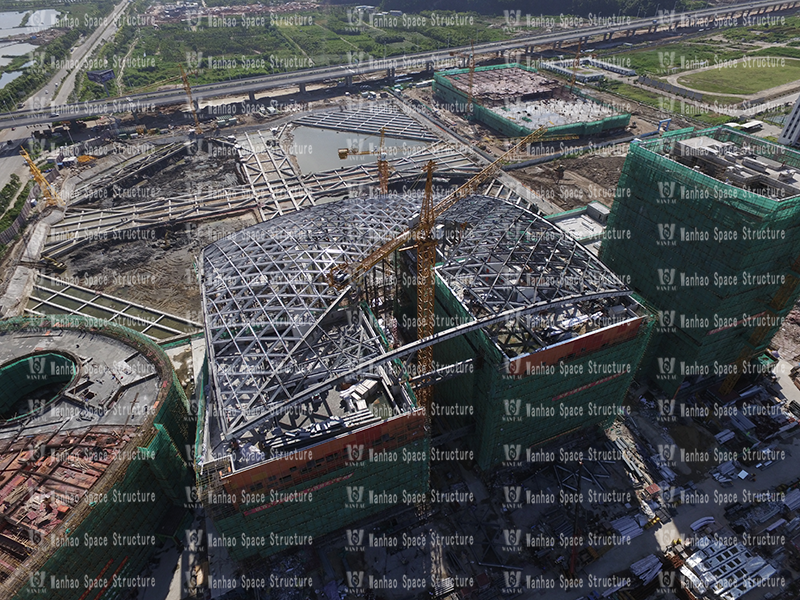

Hengqin International Science and Technology Innovation Center is located in Hengqin New District, Zhuhai City, Guangdong Province. The land area for the first phase of this project is 22119㎡, with a total construction area of 63486.63㎡. Among them, the 1 # building (China-Latin Economic and Trade Park) has a building height of 36.5m, the structural form is a skeleton air pillow membrane structure, and the upper part is a steel structure single-layer mesh shell + ETFE air pillow membrane cover, as shown in the figure below. The total area of the air pillow membrane is about 8000 square meters, with a total of 730 air pillows, 93 open sunroofs, composed of more than 3,000 members, a total steel volume of more than 1,700 tons, and a large single structure with complex structures. The highest elevation of the structure is 45.68 meters, the center's maximum span is about 90 meters, the entire building is novel, beautiful in shape, and uses a number of new technologies. The establishment of this project adds a touch of color to the construction of the Hengqin International Science and Technology Innovation Center and the China-Latin America Economic and Trade Park. After completion, it has been highly recognized by construction units and government agencies.

The project was completed by Ningbo Wanhao Space Structure Engineering Co., Ltd. in-depth design, processing and installation; the project was completed in December 2017.

Scene view of Hengqin International Science and Technology Innovation Center

Structural system

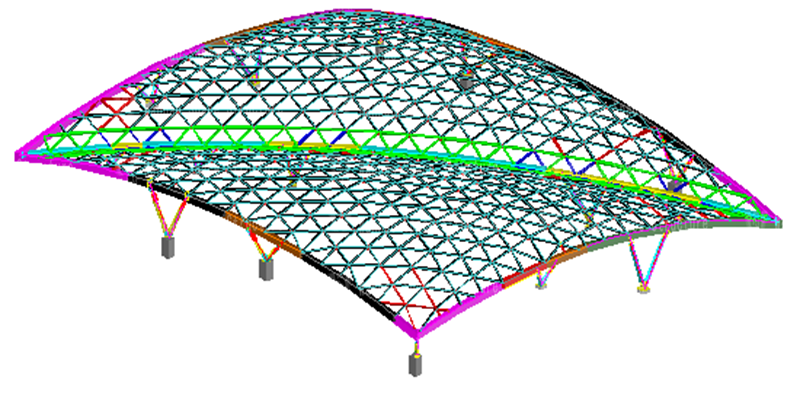

Steel structure system

The steel structure of this project is a large-span single-layer hyperboloid mesh shell structure, the surface is covered with an ETFE air pillow membrane structure, the highest point elevation of the structure is 45.68 meters; the projected surface size of the roof steel structure is 82m * 76m, and the entire roof steel structure relies on a V-shaped circle The pipe is supported on the roof, and the V-shaped support is connected with the roof steel structure through a pin. The steel beams of the roof steel structure are all box-shaped structures, and the box-shaped beams are connected to each other by a m-shaped cast steel node.

The steel structure forms include cross-stiffened steel bone columns, box-shaped reticulated shell structures, cast steel nodes, pull-resistant spherical hinge supports, etc., and the structural forms are diverse and complex.

3D model of roof steel structure

The amount of steel used in the main structure of this project is about 1,055 tons, of which 160 tons are cast steel nodes; the amount of steel used in the secondary steel structure of the membrane is about 190 tons.

2. Overview of roofing membrane structure

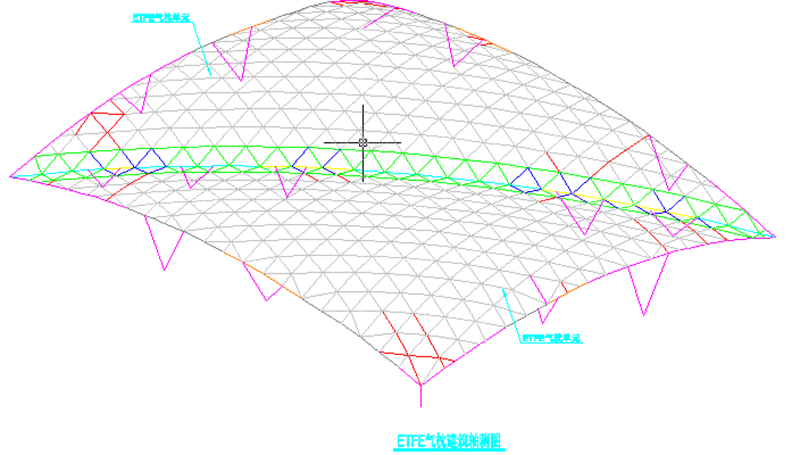

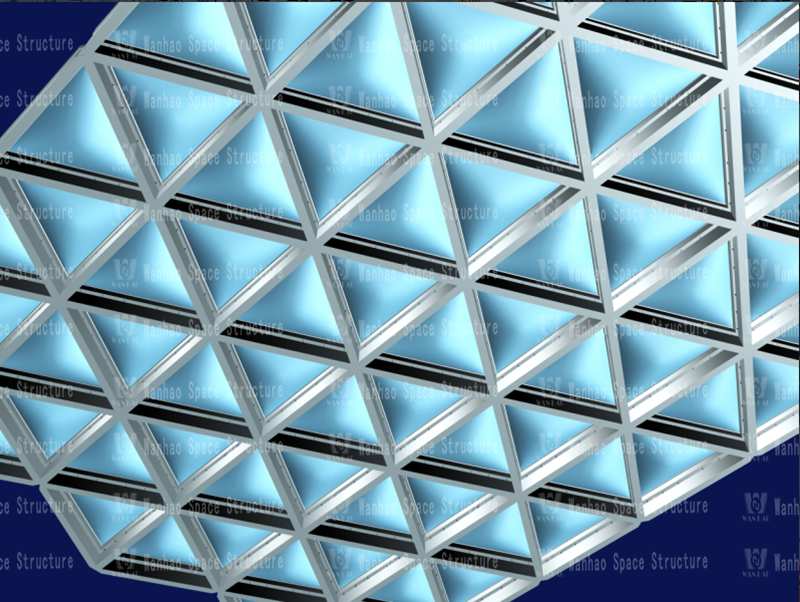

This project contains 730 (as shown in Figure 10: 364 in the lower part and 366 in the upper part) ETFE air pillows, one in each triangular area. The total area of the air pillow is about 8000㎡, of which the largest is about 12.08㎡ and the smallest is about 1.64㎡. All air pillows in this project adopt double-layer ETFE. According to experience, double-layer air pillows can meet various load combinations of this project.

ETFE Air Pillow Building Axonometric Drawing

Maximum stress distribution in the film (under negative wind pressure)

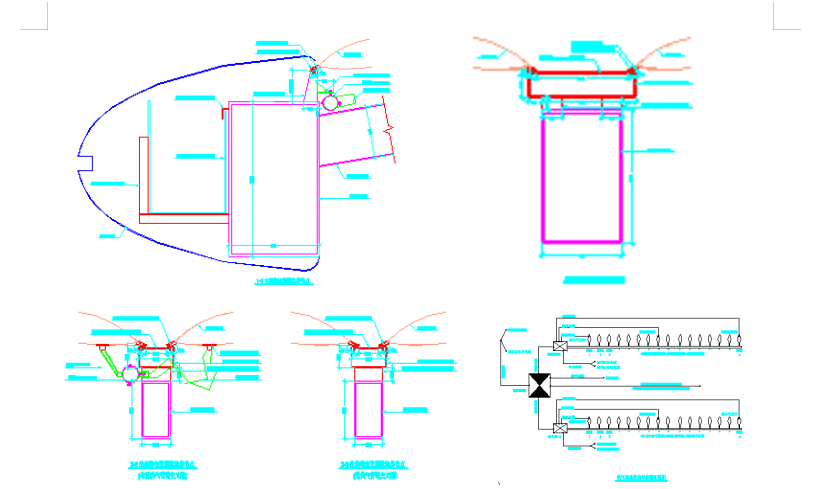

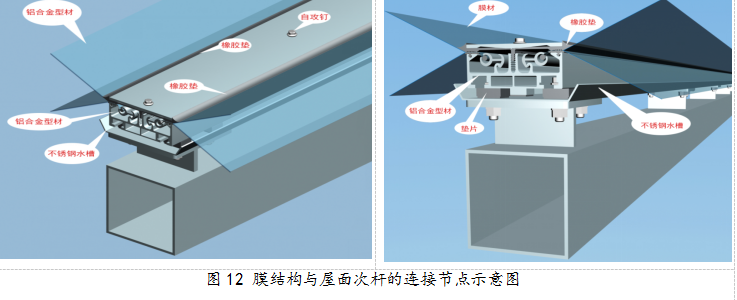

Schematic diagram of connection node of membrane structure and roof secondary pole

Membrane structure keel (aluminum alloy profile) is after the unit membrane surface is unfolded, an aluminum alloy fastener of the corresponding length is penetrated at the edge of the membrane rope, and then the aluminum profile is fixed on the secondary member by bolts and self-tapping screws.

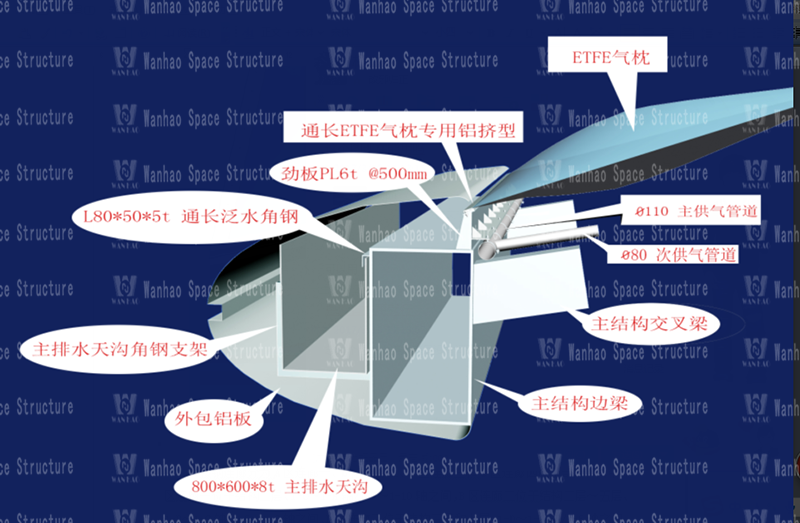

Schematic diagram of connection node of membrane structure and roof main rod

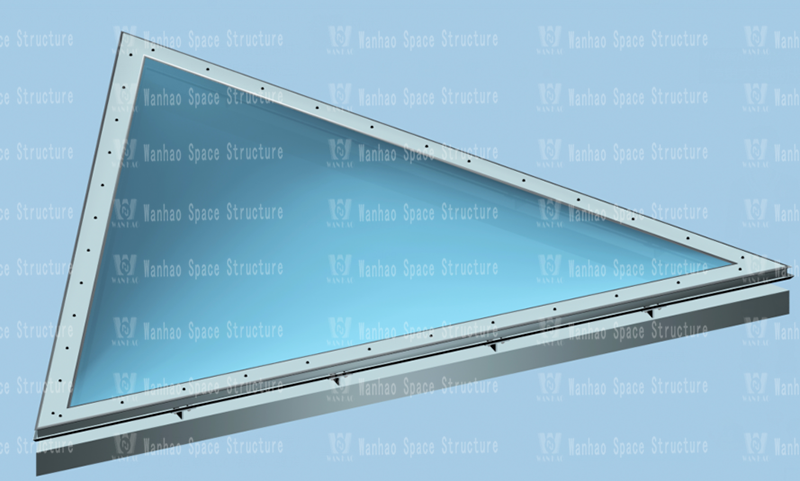

Membrane structure with each triangle of the roof structure as a unit

Roofing membrane structure looking down effect picture

Construction difficulties

According to the overall construction period, the project is urgent, and the total construction period of the steel structure project does not exceed 60 days. The steel structure weighs about 1,700 tons, including curved reticulated shells, V-shaped supports, cast steel nodes, universal bearings, and other processing cycles. The hyperboloid structure system, some of which are connected by radial spherical plain bearings, cannot maintain themselves during the installation process. The structure is stable, and temporary vertical support needs to be added to affect the installation progress. There are many components and specifications, and a reasonable delivery order is also a guarantee of the construction period. There are many winds and heavy rains in Zhuhai, and there are many uncertain factors affecting the construction period. Long material procurement cycle. Although many difficulties, Wanhao has solved them one by one smoothly.

Fourth, the steel shell construction scheme

1. Introduction to installation method

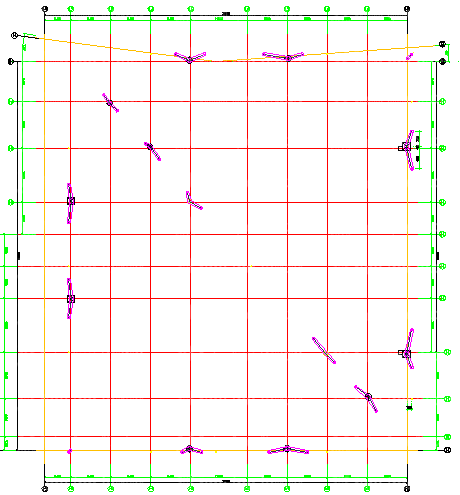

The main steel beam uses the performance and hoisting radius of the on-site C7052 walking tower crane. First install 1 / 1-J and 1-10 axis main box steel beams and reticulated shell units, and then move the tower crane to the center line to install 1-A, 1-2 axis main steel beams and diagonal main steel beams are installed in order to form a stable system after the roof lattice shell is installed.

The reticulated shell is first assembled on the ground into a unit and then lifted by a tower crane. The reticulated shell is installed from the corner to the middle in order to ensure the overall stability of the structure.

2. Installation steps

(1) Installation of roof supports, cast steel and steel columns

When installing a steel column, pay attention to the lower insert plate of the steel column and the embedded component before welding and installation.

Roof steel column layout

(2) Roof girder installation (33 sections in total)

The installation sequence of the roof girder is the same according to the installation and welding sequence of the lattice shell

V. Economic indicators

The amount of steel used in the main structure of this project is about 1,100 tons, and the cast steel node is 160 tons; the amount of steel used in the secondary steel structure of the film is about 190 tons, and the total area of the air pillow film is about 8,000 square meters.

Project photos

Copyright © Zhejiang Wanhao Group Co., Ltd. All Rights Reserved.

Sitemap | Technical Support