Search

"Technical Regulations for Membrane Structures" CECS 158, according to the types of substrates and coatings, membrane materials are divided into three categories:

Type G (usually called PTFE membrane)

P type (usually called PVC film)

Class E (usually called ETFE film)

In practical applications, due to different functions, the following terms are often encountered:

Outer membrane, high permeability membrane, mesh membrane, sound-absorbing membrane.

So, what are their characteristics?

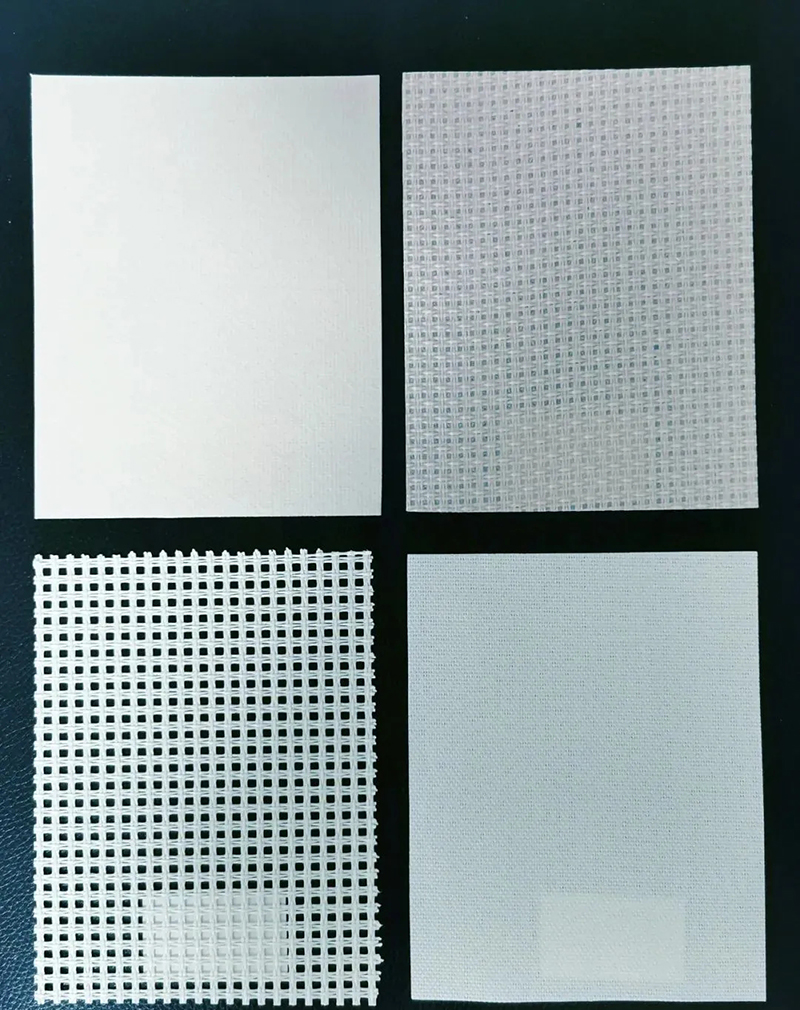

Outer membrane (upper left in the picture)

It is the most commonly used membrane material, consisting of a high-strength fiber fabric coated with a durable protective coating. It is characterized by high strength, good self-cleaning property, wind and rain (impermeable, impermeable); a certain light transmittance (8~15%, light but not transparent), no sound absorption.

High permeability membrane (upper right in the picture)

Compared with the outer film, the weaving distance of the base material yarn is increased, and the transparency of the coating is adjusted at the same time to increase the light transmittance, and the coating is still fully covered. It is characterized by high light transmittance (20~60%, light but not transparent), good self-cleaning, wind and rain (impermeable, impermeable); the strength is lower than the outer membrane, and no sound absorption.

Mesh film (bottom left in the picture)

The base yarn has a large weaving distance, and the coating is no longer full, forming a certain open rate (20~70%). It is characterized by high light transmittance (30~70%, transparent and transparent), good decorative shading effect; lower strength than outer membrane, breathable and water-permeable, and no sound absorption.

Sound-absorbing film (bottom right in the picture)

Compared with the mesh film, the opening rate is very small (1~3%), and the coating process is adjusted to improve the sound absorption effect. It is characterized by good sound absorption effect (sound absorption coefficient 0.4~0.75), light transmission and opacity (20~40%), air permeability and water resistance, and lower strength and self-cleaning properties than outer membrane.

Membrane materials of different materials-Type G (PTFE) and Type P (PVC), have their own corresponding models to meet the above various functions. Since the E-type (ETFE) film material is a homogeneous material without a fabric substrate, there is no grid film and sound-absorbing film, and different light transmittances (20~90%) can be achieved by adjusting the diameter and density of the printing and plating points.

Membrane materials of different materials (PTFE, PVC, ETFE) and different functions (outer membrane, high permeability membrane, mesh membrane, sound-absorbing membrane) have their own advantages and disadvantages. Therefore, the strengths and weaknesses should be maximized when selecting membrane materials, and suitable membrane materials should be used in suitable places.

Outer membrane | High permeability membrane | Mesh film | Sound-absorbing film | |

strength | Very high | high | high | general |

F(%) | 0 | 0 | 20~70 | 1~3 |

Transmittance(%) | 8~15 | 20~60 | 30~70 | 20~40 |

Perspective | N | N | Y | N |

Breathable | N | N | Y | Y |

permeable | N | N | Y | N |

Sound absorption coefficient | reflection | reflection | penetrate | 0.4~0.75 |

Self-cleaning | well | good | better | general |

Copyright © Zhejiang Wanhao Group Co., Ltd. All Rights Reserved.

Sitemap | Technical Support