Search

Sump capping is a measure of energy saving and environmental protection. The use of membrane structure not only solves the pollution phenomenon of waste gas in sump, but also meets the discharge requirements of waste gas treatment. The traditional sewage pool is covered by glass steel, sun plate, etc. However, with the continuous serious waste gas pollution of sewage pool, the traditional sewage pool covering measures have been unable to meet the increasingly serious waste gas pollution requirements, and the glass steel or sun plate caused different degrees of corrosion, reducing the deodorization rate of sewage pool covering.

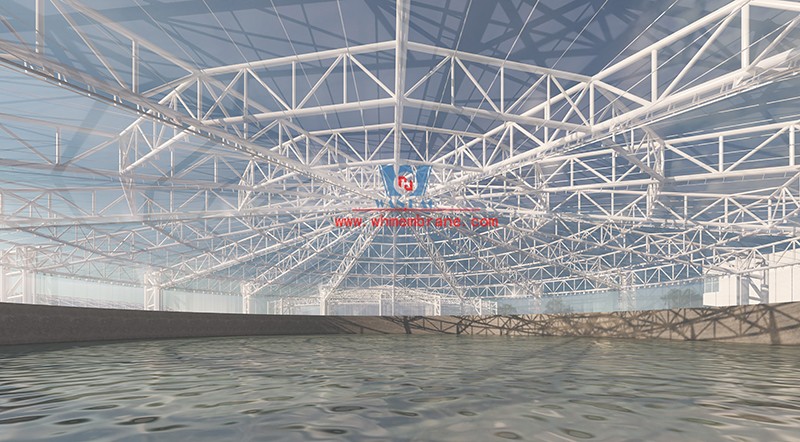

With the continuous maturity of industrial technology, sewage pool capping is generally used in the form of anti-hanging membrane structure, to treat the waste gas in the sewage pool. This structure adopts the principle of anti-hanging membrane material, the steel structure as the outer layer of membrane material, so as to effectively avoid the corrosion of the steel structure by the exhaust gas in the pool, prolong the service life of the steel structure, and improve the anti-hanging membrane structure of the exhaust gas deodorization rate. Membrane structure sewage pool capping method is novel, using the form of membrane reverse hanging, not only novel shape beautiful appearance, and adapt to a variety of environment of the large span pool body building, more solid than the traditional sewage pool capping, can also solve the traditional capping way in the large span pool body construction difficulties, more favored by the sewage pool project.

Film material performance is good: the film material used for reverse lifting has high corrosion resistance, tear resistance and oxidation resistance, which can overcome the adverse environment (such as wind load, snow load). High waste gas collection efficiency: The anti-hanging membrane structure of the sewage tank is popular because of its high waste gas collection rate, so as to achieve zero pollution to the environment. Before the installation of the sewage pool, we should first plan the deployment of the project related staff and formulate a detailed installation and construction process. Before installation, it is necessary to check whether there is damage and folding on the outer surface of the membrane, whether there is scattered in the hot melt joint, whether there is strain or rust in the bolt and aluminum alloy lamination, and whether the coating of cable and anchor is damaged. Also according to the conditions of the site and the construction plan to build the membrane body open platform, install the safety network, for large membrane structure buildings, to collect the weather information of the installation time. Pay close attention to the wind direction in the process of capping and installing the sewage tank to prevent the film body from shaking. In case of strong wind or heavy rain, the construction should be stopped immediately and the corresponding protective countermeasures should be adopted.

Case: The Golermu sewage treatment Pool thermal insulation and stamping project undertaken by Ningbo Wanhao Spatial Structure Engineering Co., Ltd. won the 2022 "Science and Technology Innovation Award" of China Steel Structure Association. The project is completed by the combination of different pools with diameters of 60 meters and 30 meters. Soft glass ETFE film material is used as the base material. It has the characteristics of high transmittance, light weight, soft and tensioned, good seismic effect and so on. It perfectly meets the requirements of sunlight and ultraviolet irradiation of sewage treatment tank. It belongs to the first application project of ETFE in industrial sewage insulation capping in China. Wanhao adhering to the "customer first, safe production, quality first" concept of safety construction, won the majority of customers a good reputation! In the future, we will continue to work hard to make great strides in the field of membrane structure, obtain more honors and commendations, and add luster to the cause of membrane structure in China.

Copyright © Zhejiang Wanhao Group Co., Ltd. All Rights Reserved.

Sitemap | Technical Support